Discover the Timeless Art of Japanese Indigo Dyeing

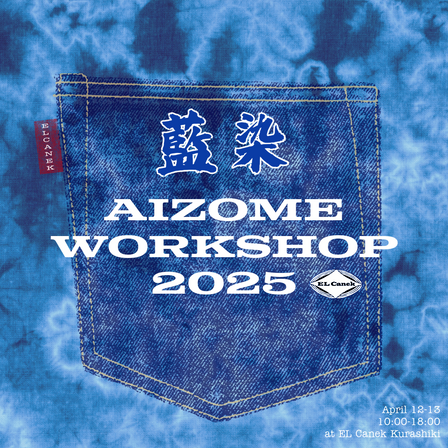

Aizome Workshop 2025 | April 12 & 13 at EL Canek Kurashiki

Step into the rich world of Japanese indigo dyeing, or Aizome—a centuries-old tradition that originated from China and flourished during Japan’s Edo period as the “color of the people.” Known for its deep blue hue and natural antibacterial properties, indigo dyeing was historically used to prevent skin conditions and protect against poisonous insects.

At our upcoming Aizome Workshop, you’ll get a behind-the-scenes look at how we craft our SH-01 linen shirt in collaboration with TKD Works, a linen fabric maker from Shizuoka. Designed by EL Canek founder Masayuki Kanatani, the shirt features unique elements such as an asymmetrical front button closure and hidden buttonholes on the sleeves. Each piece is carefully hand-dyed by skilled artisans, making every shirt one-of-a-kind.

The Indigo Dyeing Process

Indigo dyeing uses the power of nature. The indigo plant leaves, when exposed to air or water, transform into a vibrant blue dye called indigo. The process of dyeing allows for creative expression—the more times you dye the fabric, the deeper the color, and the more variation in pattern you can achieve.

For fresh leaf dyeing, known as 生葉染め (Namaha-zome), the leaves are blended with 10–20 times their volume in water, then strained to create a dye bath. Fabrics are gently soaked and aerated to trigger oxidation—the magical moment when the dye turns from green to deep blue. It’s essential to oxidize the fabric after dyeing, as indigo turns blue only when it reacts with air.

We’ll also explore the traditional fermentation-based method called “Hondate” or “Hell Date” (本建て/地獄建て), where indigo is reduced into a water-soluble state using fermented Sukumo (composted indigo leaves). This ancient process uses enzymes and time to unlock the full power of indigo—a truly time-honored technique passed down through generations.

Join Us for the Experience

On April 12 (Sat) & 13 (Sun), we’ll be hosting a special indigo dyeing event at our EL Canek Kurashiki store.

We’re honored to welcome natural dye artist Ms. Asayama, who will lead the workshop using both fresh-leaf and traditional fermentation techniques.

We’ll provide items like T-shirts, handkerchiefs, and stoles to dye, but you’re also welcome to bring your own pieces (shirts, sneakers, scarves, etc.) to transform with your personal touch.

Come feel the joy of hand-dyeing and immerse yourself in a piece of Japanese culture 🫶

Reserve Your Spot Now

🔗https://elcanekjeanslab.com/products/linen-sh-01?variant=40083523633223

📩Or DM us on instagram @elcanekjeanslab

藍の生葉染めの方法

伝統的な染色技術として日本でも古くから親しまれてきた藍染。

古来、中国から伝わり、江戸時代には庶民の色として親しまれました。殺菌作用が強く、染めた衣服で皮膚病や毒虫を防ぎました。

藍の持つ成分は、空気や水に触れることでインディゴ(青く染まる成分)に変化します

染める回数によって色の濃さを変えたり、模様をつけたり。工夫次第でオリジナリティを出すこともできます。

藍の生葉(葉のみ)に10〜20倍の水を加えてミキサーにかける。葉が多ければ、何回かに分けて繰り返す。ゴム手袋をして、漉し布で葉を漉し、染液をつくる。

染液に布を浸して、布全体に染み渡るように布をくゆらす。15分間浸す間に布を広げ、空中でなびかせ酸化させる。

※ 藍の成分は空気に触れると酸化して青く発色します。発色した後では生地に色がつかないので、発色する前に、生地に染液を染み込ませるようにして下さい。

エルカネックリネンシャツ-藍染。TKD Works様とコラボさせていただいた人気商品。追加料金で職人の手により藍染もさせていただきます。リネン100%で通気性も手触りも良く、初夏のこの季節におすすめの商品です。🍃真夏が始まる今の時期に大活躍間違い無し。ぜひ一枚いかがですか?お店にお立寄りの際はお気軽にご試着くださいませ。

NEWS

4月12日(土)、13日(日)の2日間、EL Canek倉敷店にて草木染め作家の浅山様にお越しいただき藍染めのワークショップを行います。Tシャツ、ハンカチ、ストールをご用意しておりますのでお気軽に遊びにいらしてください!何か染めたい物(シャツ、ハンカチ等)などがあれば持ち込んでいただいても大丈夫です。是非手染めの楽しさを体感してください🫶

Learn More

Blogs and Articles

- All

- Collaboration

- Denim Fashion

- Denim Styling

- EL Canek

- fabric factory

- Fashion

- Indigo dyeing

- interview

- Japanese artisans

- Japanese denim

- Jeans

- Kurashiki Historical Square

- Linen

- Made in Japan

- Masayuki Kanatani

- New Collections

- News

- Spring

- Spring Collection

- SS23

- Sustainable Fashion

- TKD Works

- Unisex

- Unisex Jeans

Okamoto Textile: Where Our Denim Fabric is Made

At EL Canek, we take great pride in the craftsmanship and attention to detail that goes into creating our handmade jeans. Central to this process is the fabric we use, which is made at Okamoto Textile in Ibara Okayama, Japan.

The Production Process

Okamoto Textile follows a meticulous production process to create high-quality denim fabric. It all begins with the weaving process, where vertical and horizontal threads are combined to create the fabric. The dyed threads undergo sizing treatment to make them easier to weave. Each thread is carefully passed through a series of droppers, wires, and reeds to ensure smooth movement during the weaving process.

There are different types of weaving machines used at Okamoto Textile. The shuttle loom, for example, carries the horizontal threads in a wooden shuttle, while other machines like the rapier loom, air jet loom, water jet loom, and gripper loom utilize different mechanisms to carry the horizontal threads.

To ensure the highest quality, Okamoto Textile has made improvements to its shuttle looms. While older looms tend to produce fabric with higher defect rates, Okamoto Textile's shuttle looms have undergone structural improvements to create fabric that meets the current quality standards. The result is fabric with a unique, untreated texture that is not subjected to excessive tension.

In addition to shuttle looms, Okamoto Textile also utilizes rapier looms and has a total of 10 shuttle looms and 20 rapier looms in its production facility. These machines enable the production of original and distinctive fabrics.

Craftsmanship and Attention to Detail

At EL Canek, we believe that the foundation of exceptional jeans lies in the fabric. That's why we have chosen to work with Okamoto Textile, a company that shares our commitment to craftsmanship and attention to detail. Every step of the production process, from choosing the fabric to pattern-making to hand-sewing, is carried out with meticulous care and precision.

Okamoto Textile's use of vintage machines adds to the uniqueness of the denim fabric we use for our jeans. These machines, known for their quality and reliability, produce fabric that embodies the essence of traditional Japanese craftsmanship.

Preserving Tradition and Creating the Future

The partnership between EL Canek and Okamoto Textile is a testament to our shared values of preserving tradition while embracing innovation. By combining handcrafted techniques with modern manufacturing processes, we create denim fabric that is not only of the highest quality but also tells a story of Japanese craftsmanship and heritage.

At EL Canek, we are proud to collaborate with Okamoto Textile and to bring you jeans that are made with love and attention to detail. The fabric from Okamoto Textile forms the foundation of our handmade jeans, and we are excited to share this exceptional fabric with you.

Experience the craftsmanship and quality of EL Canek jeans, made with fabric from Okamoto Textile. Step into the future of denim with us and embrace the legacy of Japanese craftsmanship.

Find out more about Okamoto Textile

Learn More

Spring is here, and we are so excited to bring you our new items.

Learn More